Nothing is comparable to the success of your business. We understand how important having the right tools to achieve the success you so greatly desire is. That is why we have worked tirelessly over many years to produce the best of the best in bottle flipping devices for all the canning and bottling factories around the world.

Our current customer base is vast and in many big brands like Coke in Brisbane, Heinz, Carleton and many more. But don't let our big customers intimidate you, we are happy to work with businesses of all sizes and budgets.

Let's work together to make your business a success!

We are in the custom design business for all your can, bottle or any other item that needs to be flipped, twisted or turned upside down inside out in every which way you could imagine. Since 2005 we have had this drive to create the kinds of products all manufacturers could possibly ever ask for, however there is always something new to learn and a new design to be created, so if you don't see what you need from our product range feel free to get in touch and we can get working on your needs.

Besides our Invertors are there other options?

Yes, but let's break down some important factors in why our invertors are a smarter option than others...

We will not deny that it's quite a skill to make the wire twists, and very few are able to make them to the tight tolerances needed to keep the products stable.

So in order to compensate the metal twist manufacturers have to make them quite long.

Most production lines run multiple products on different shifts, and need to change over the conveyor setup for a different can/bottle size. So when changing these long, heavy wire twists, they are prone to getting dropped and bent out of shape. Its also a long process changing them over.

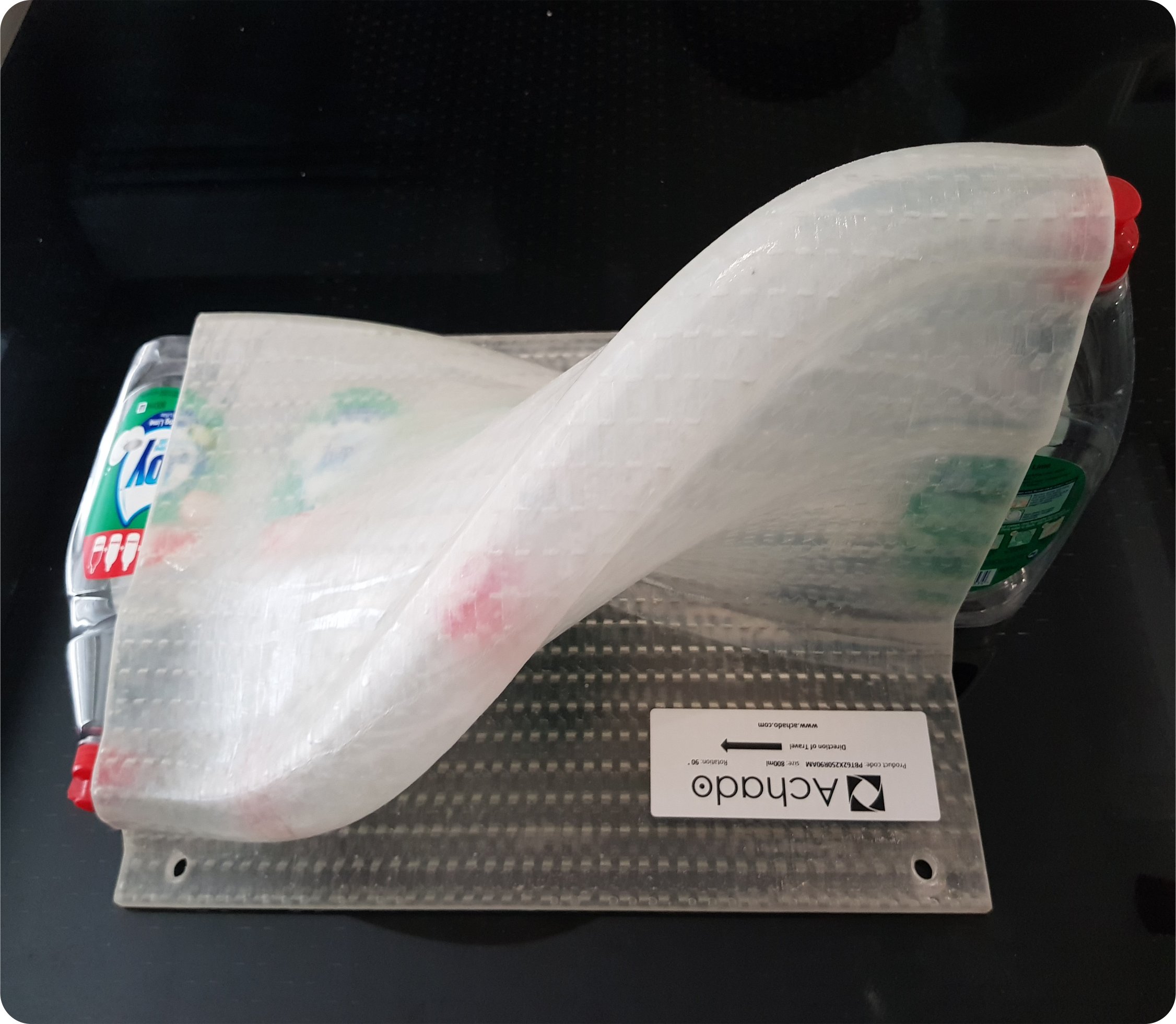

The metal twists are usually 1 to 2 metres long. The ones from Achado are 320mm.

Our Twist Invertors can be installed horizontally on top of a section of conveyor. Unlike the wire ones that have to be installed on a downhill angle, and so you have to have the infeed conveyor higher than the outfeed, and because you have to have 2 conveyors, that's 2 motors and VFD's and 2 settings in the PLC for the electrician to setup.

*We do acknowledge that on high speed lines, like say over 800 cans per minute, it is best to install our invertors on a downhill as well.

Because these invertors are so compact and can be easily installed on an existing conveyor, they get used where wire twists wouldn't. For instance, cheap date coding inkjet printers work best when printing downwards - but they usually print the batch number etc on the underside of cans. So some places use 2 invertors with a printer in between so they can easily print date codes on the bottom of cans. They would never do this with wire twists, because you'd have to have conveyors at 3 levels, 3 motors, and many metres of distance... and floor space is expensive so this is not an ideal choice for any manufacturer.

Sadly the wire twisting invertors are unstable. Based on the experience of the manufacturer who has been on the factory floor in various locations there has been incidents of cans often falling over at the exit, and have to be rejected later in the line... the Achado invertors do not do this when installed correctly.

Another perk is that whilst the metal twists take long to change out these 'plastic' invertors can be changed over in seconds when changing can sizes. You just lift them off the mounting pins, and drop the replacement one on.

Something to keep in mind is that the wire twists wear quite quickly because you have metal on metal rubbing against each other causing a faster wear and tear. If they have the clip on nylon wear strips, those wear out even faster, because they are round, the cans make point contact with them, and wear out of tolerance in months - so the nylon wear strips have to be replaced every few months.

However the Achado ones last WAY longer and have an insane longevity.

One of the first devices installed back in 2005 are STILL RUNNING!!!

If we are to be honest, wire twists are not really a great comparison, although they are a great option for some there are other companies out there who manufacture products just like ours... well, not quite like ours.

You see it is not just the design of the invertors themselves, but the highly automated programming and machining process that truly sets us apart from all the others... not to mention the ultimate secret is the shape of the tunnel.

Achado has created a top secret highly optimized mathematically perfect shape for flipping cans over. The competition just naively create a helical tunnel with enough clearance for cans to go trough and not get stuck.... fortunately this is not the approach taken by us, we look to providing something that is worth the investment. Because we know that it can be frustrating for anyone looking to buy a quality product that will last the many many runs done by their factory and not find it even after spending the money.

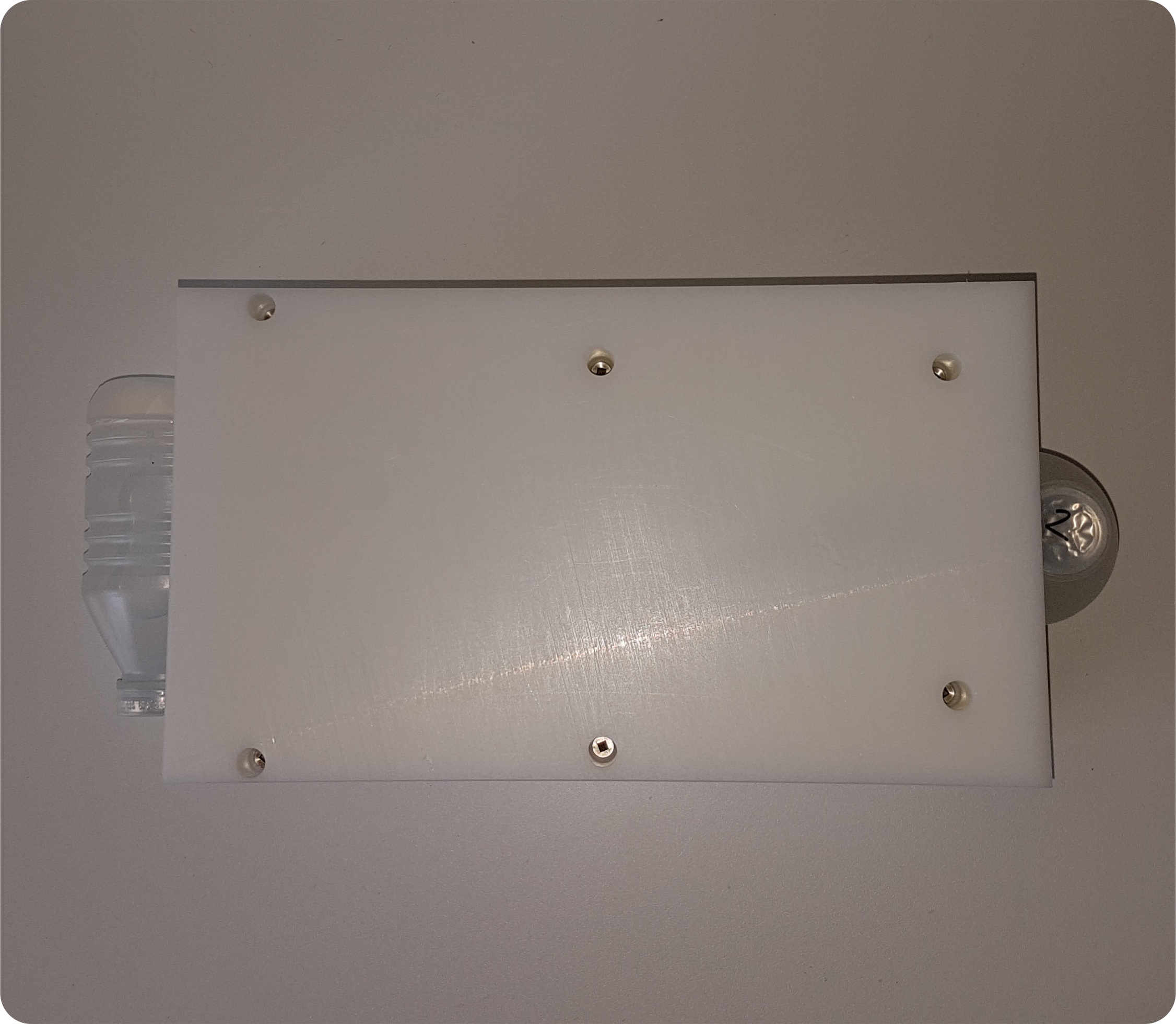

Below you will see a few examples of the different types of invertors that are typically used by many manufacturers and factories on their production lines... but if there's something you don't see feel free to get in contact to see how we can help make the invertor of your dreams!

Also going by many names, these 90 degree twist boxes enable bottles, cans, jar, bottles etc to be tipped on their side.

Also known as Can Flippers, Twisted Can Races, Upenders, Invertors, Revertors – we make them for bottles, jars, tubs, cans, bottles. They turn containers upside down

With a full 360 degree rotation inside the box, products come out the same way they went in. This agitates the contents. These boxes can have a straight section included in the middle with a slot in the bottom for rinsing purposes.

We can custom make twists to suit many different applications. We make 90˚ tippers and 45˚ tippers for Calmac Engineering for their gravity rinser. We can ramp bottles, cans, jars off the end of a conveyor, rotate them and have them roll off onto existing races. If you have an unusual application, please feel free to contact us.