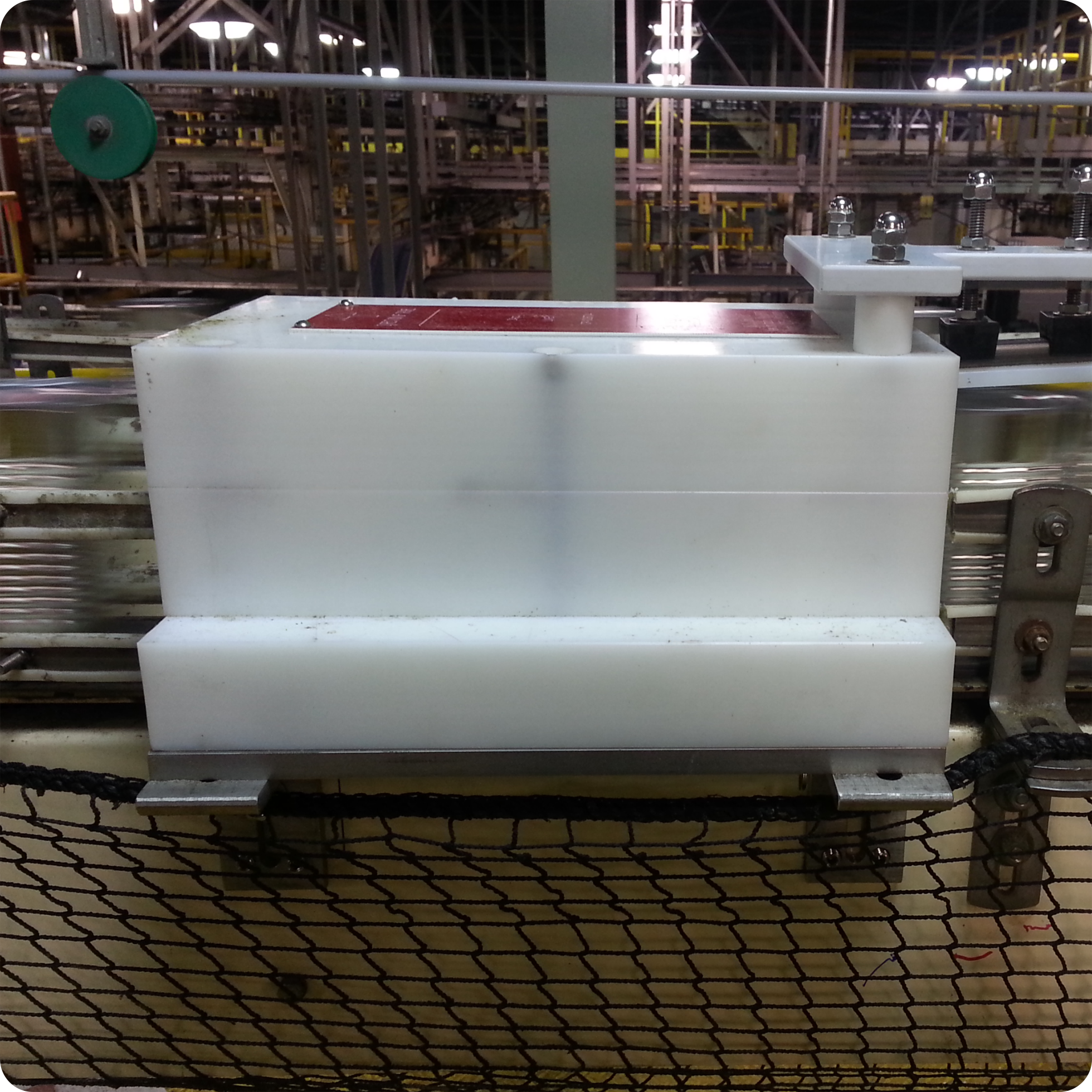

These devices are specifically designed and manufactured to be the highest quality flippers for anyone in the canning and bottling industry. Using the best raw materials these products can last much longer than other devices made from wire, which is more common because of costs. Yes the wire twisting device may cost less but they are cumbersome to install, replace and take ages to install and replace.

Our devices take seconds to replace and last much longer than most because of the quality of the raw materials used.

Most production lines run multiple products on different shifts, and need to change over the conveyor setup for a different can/bottle size. So when changing the longer, heavy wire twists, they are prone to getting dropped and bent out of shape which then requires new ones to be made which cuts into production time which anyone in the industry will tell you is not ideal and can cause losses financially because of delays.

So why waste your time on anything other than the best?

Maybe you are unsure where exactly to use our products?

Not to worry, we have expanded on a few places and applications that you could use our devices in your factory.

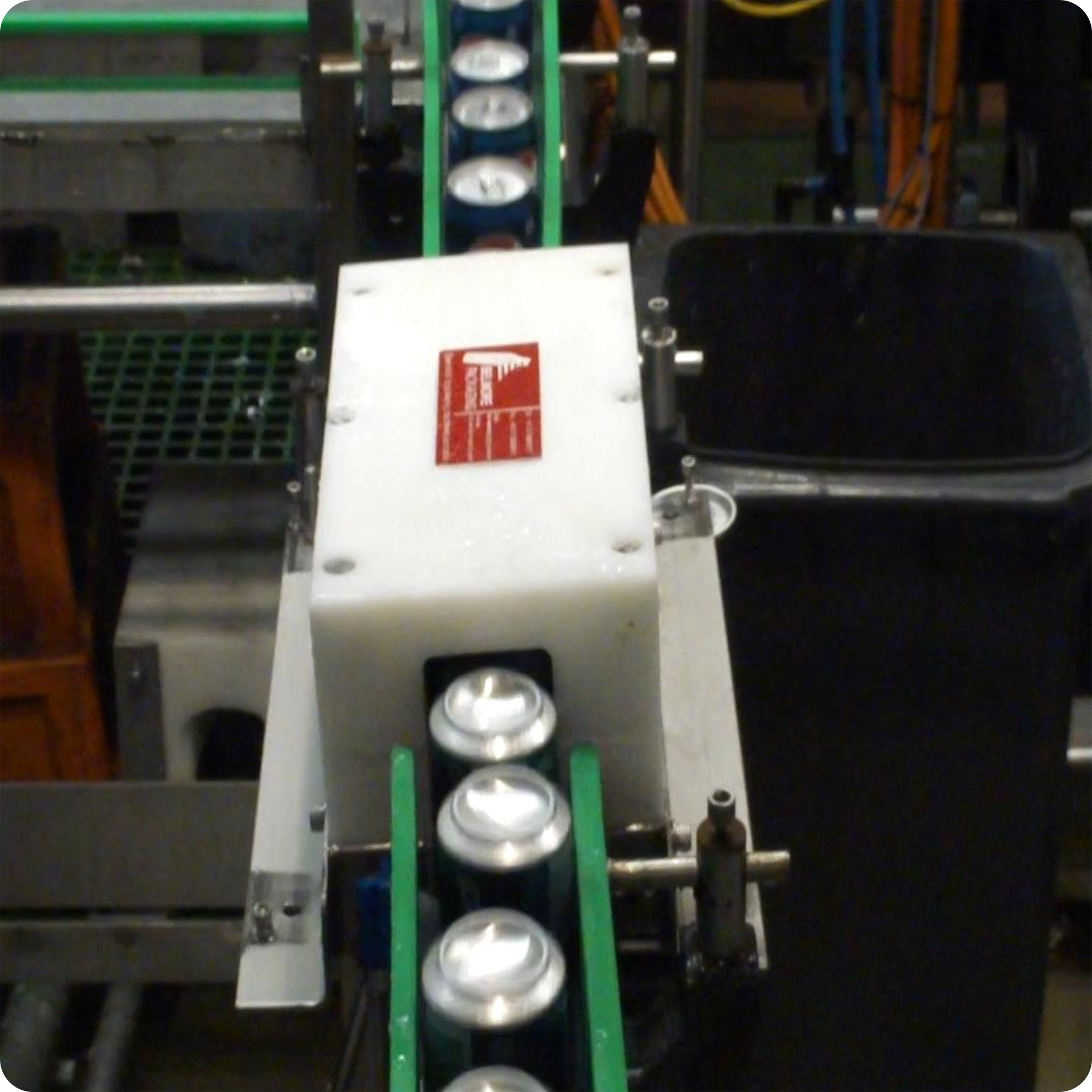

Did you know that milk powder cans are often filled upside down? But not just that, quite a few beverages are filled upside down too! So it would make sense that we would produce a 'can flipper' in order to consistently and effectively flip a can or bottle upside down with ease.

But now that your product is upside down and filled what do you do next?

We have the solution to that... we simply flip the can upright again! That is why you may need more than one of our devices because some products need to be flipped upside down for filling or even cleaning but then need to be flipped once more for packaging purposes which is where the second flipper would come into play on your production line.

Perhaps the most common use of our product is for rinsing the empty containers on the assembly line. Flipping containers upside down, and rinsing with air or water, ensures debris is cleaned out before the filling process.

Sometimes the bottle or can requires more than one wash or maybe even has a sterilization process that happens which requires the container to be upside down in order to allow the sanitized water to drip down and out of the bottle. This now allows the actual beverage or product to fill the empty container and be re-flipped to have it ready for packaging.

Wetting the cap with the hot contents (or contents containing preservatives) helps to prevent mould growing in the lid during storage. This requires us to manufacture twist inverters that either tip a bit and then tip back up or just rotate a full 360 degrees in order to accomplish the required 'wetting' of the caps.

It may seem like a small detail but it is so necessary especially when you are processing at rapid paces to meet industry demands.

Containers that get wet during the cooking or pasteurizing process are dried effectively if blown after being turned upside down, which is another great reason why our products are perfect for this application. Another great point is that sterilizing and drying the empty container stops contamination of the product which is obviously required for food products which is an application made easier with our device.

Our products twist and turn the empty containers upside down (and back again) in order to ensure they get dried effectively!

Another important reason to use our devices is the ease of packaging... In today's increased pace of production supermarkets are now more likely to demand that products are delivered 'shelf ready'. Meaning that they can stock the shelves quicker if your products are easy to pull out the box and shove onto the shelf for the consumers to purchase.

This is why products filled upside down need to be upended before packaging, making our device, that flips your bottles/cans upside down and back again, the ideal addition to your factory.